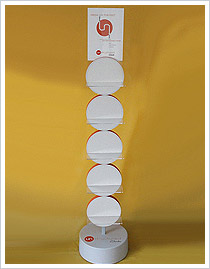

Custom Shoe Tower

Title: Shoe Floor Display

(Click on thumbnail to enlarge)

Description:

We were recently contracted by a repeat customer to develop a freestanding shoe display that would present 10 current styles. At Dewitt Plastics, our strength lies in our ability to provide customers with a single source solution for challenging fabrication projects.

In this case, the customer had a general design concept that required interpretation necessary to balance design objectives and fabrication parameters. The display would be provided to independent retailers and needed to present a professional image for the brand while being easily shipped and assembled.

The display was constructed using a diverse pallet of materials. ¾" Sintra panels were laminated and CNC shaped, screen printed, and edge painted. Powder coated square steel tubing provided the vertical alignment while simultaneously ensuring consistent orientation of the individual discs. Acrylic shelves and sign holder were cut, polished, and assembled, and color matched HIPS was vacuum formed to create the base cover.

To provide consistency with the customer's broader brand identification, all colors were PMS matched. Functional details such as floor levelers were incorporated to ensure safe and steady display at retail. In a cooperative effort, our customer provided printed header cards to be included and packed with the completed display.

Using only 1.5 square feet of floor space, this 72" tall display was able to be multi-carton packed for UPS shipment. Following initial distribution to the customer's distribution center, we retained a predetermined inventory in our warehouse for drop shipments as requested. At Dewitt Plastics customer service extends beyond simple order processing. To learn more contact us directly.

Specifications:

- Product Name

- Unstructured Shoe Display Tower

- Product Description

- Custom Shoe Tower Display

- Capabilities Applied/Processes

-

- Primary:

Thermoforming

CNC Machining

Acrylic Fabrication / Finishing - Secondary:

Solvent bonding

Screen Printing

Painting

Pad Printing

Assembly and Packaging

- Primary:

- Equipment Used to Manufacture Part

-

- Vacuum Former

CNC Router - Pad Printer

Powder Coating Line

- Vacuum Former

- Overall Part Dimensions

- 14.5" diameter x 72" tall assembled

- Tightest Tolerances

- As necessary for design application

- Material Used

-

- Base: MDF with leveling inserts

Base Cover: HIPS

Vertical Support: Square CRS tubing - Display Discs: Sintra

Shelves: .250 Acrylic

Sign Holder: .125 Acrylic

- Base: MDF with leveling inserts

- Material Finish

- Formed Materials: Industry standard

Acrylic: Flame polished

- Industry for Use

- Retail Footwear Display

- Delivery Location

- Nationwide

- Standards Met

- Joint Specifications, 2D CAD Drawing

Print This Page

Print This Page