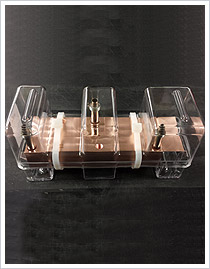

Custom Slab Mirror Package

Title: Slab Mirror Shipping Package

(Click on thumbnail to enlarge)

Description:

The project highlighted here was created for a manufacturer of high value optics systems that was in need of a package to address numerous deficiencies in their previous design.

To address all aspects of package requirements, the new design needed to offer a multitude of solutions. Of particular concern was a requirement for an inert material and a final product that had no contamination, including any residual mold releases or similar by-products of the manufacturing process. In addition, the design needed to be adaptable to a range of sizes, isolate critical product elements, be adequately durable to protect a12 pound content, provide stacking features, and be cost effective as the package would be a one way shipper, replacing a package that previously required return to the manufacturer.

To add to the challenge we were provided with only a redacted part drawing with minimal product detail. At Dewitt we specialize in challenging projects such as this, and quickly developed a preliminary concept prototype for the customer. Our concept and approach to addressing the package objectives resonated with the customer's engineering staff and agreement was made to proceed with development. Because of the proprietary nature of this product, a non-disclosure agreement was required to allow us to proceed with detailed product assessment.

In a cooperative effort, the customer's engineers worked with our staff to lay out critical dimensional details. This was followed by concept studies and the creation of prototypes for functional compliance. Material gauge assessments were also completed to identify optimal strength and protective capabilities. Various closure options were evaluated taking into account specific handling requirements identified by the customer. Design details were then fine-tuned to facilitate product insertion.

The package was thermoformed using PETG, a strong and extremely durable plastic exhibiting excellent clarity and molding properties. Special mold surface treatments were utilized to provide effective molding conditions while ensuring that the important non-contamination requirements were met. Secondary trim operations were completed as a post molding operation, and completed package assemblies, comprising top, bottom, and style specific inserts were unit packed to provide simplified inventory control and further protection from external contamination prior to use. To learn more contact us directly.

Specifications:

- Product Name

- Slab Mirror Shipper

- Product Description

- Custom Shipping Enclosure

- Capabilities Applied/Processes

-

- Primary:

Thermoforming

CNC Routing - Secondary:

Assembly and Packaging

- Primary:

- Equipment Used to Manufacture Part

- Vacuum Former

CNC Router

- Overall Part Dimensions

- 12.5 x 3 x 2 inch; each component

- Tightest Tolerances

- + .015", -0"

- Material Used

- .125 Virgin PETG

- Material Finish

- Industry standard; no texture

- Industry for Use

- Industrial Packaging

- Volume

- 1000 units initial order.

- Delivery Location

- Northeast US; ultimately export use.

- Standards Met

- Customer Specifications, SolidWorks 3D CAD Drawing

Print This Page

Print This Page